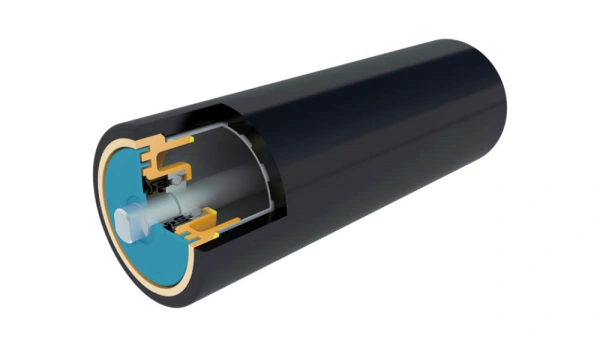

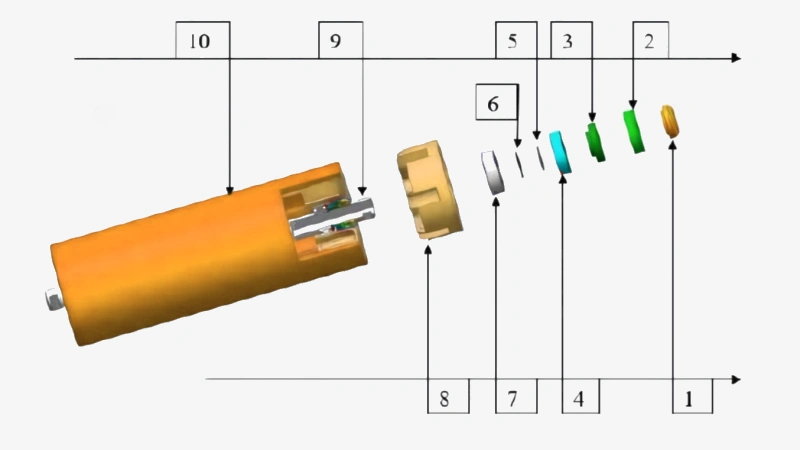

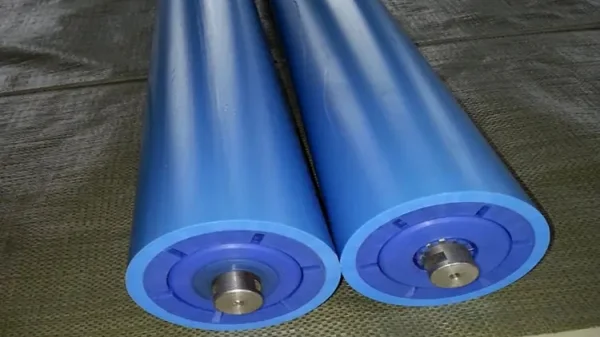

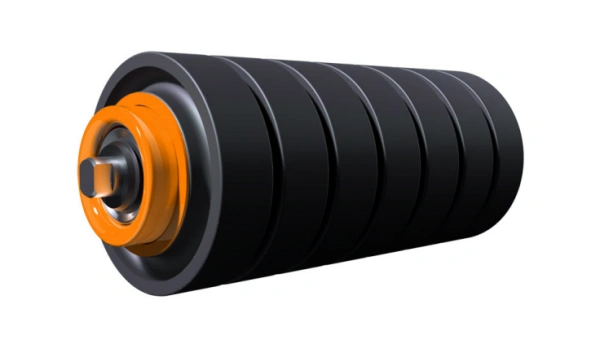

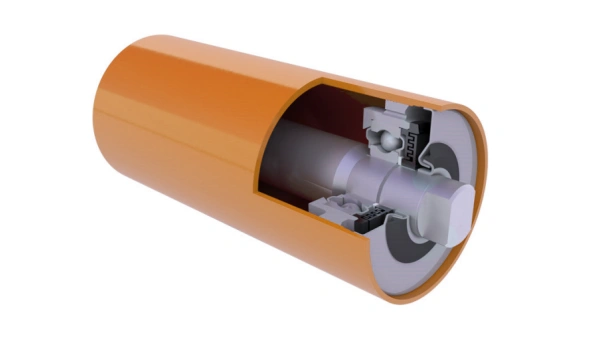

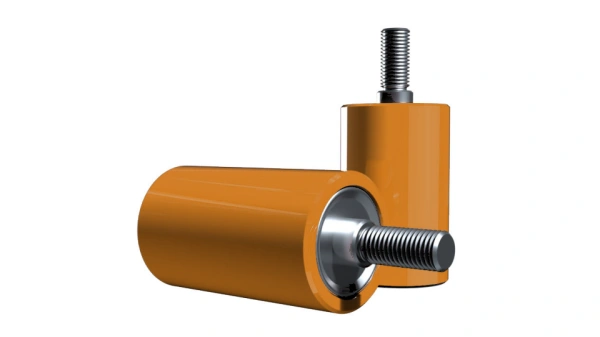

HDPE rollers or UHMWPE rollers are made of high-density polyethylene material. UHMWPE conveyor rollers are made of ultra high molecular weight polyethylene. We offer carrying idlers and return idlers made of HDPE or UHMWPE rollers.

| HDPE or UHMWPE Roller Dimension | |

| Roller Dia. (mm) | 89, 108, 133, 102, 127 |

| HDPE Tube Thickness (mm) | 9.0, 9.5, 10.5, 11.0 |

| Inner Steel Tube Dia. (mm) | 65, 80, 108, 102 |

| Inner Steel Tube Thickness. (mm) | 1.5, 2.0 |

| Roller Shaft Dia. (mm) | 20, 25 |

| Roller Length (mm) | 186 - 1632 * |

| Belt Width (mm) | 300 - 1400 |

| Bearings No. | 6204, 6205 |

| Standard | DIN, CEMA, JIS, AS,etc. |

English

English