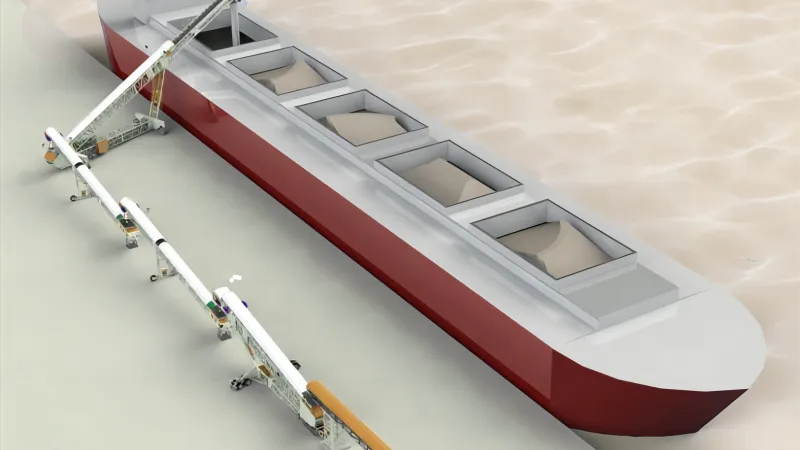

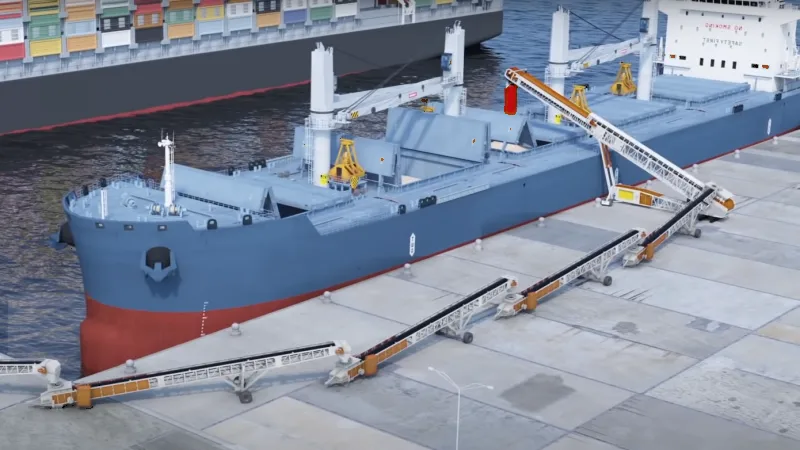

Mobile ship loading are versatile and flexible solutions for loading bulk materials onto ships, particularly in locations where fixed infrastructure is limited or impractical. These solutions are designed to be easily transportable and can be deployed at various sites as needed.

Mobile Ship Loading

Mobile Ship Loading Solutions of Bulk Materials

Advantage & Highlights

-

Excellent Mobility

All equipment, except fixed belt conveyors, can be mounted on wheels or tracks to get mobility. The operators can move these machines along the dock or quay. This mobility enables them to serve multiple berths or loading points within a port or terminal.

-

Telescopic Conveyor

A telescopic conveyor is a common feature of mobile ship loading systems. This conveyor can extend and retract, providing flexibility in reaching different parts of the ship's hold and accommodating various vessel sizes and configurations.

-

Adjustable Loading Spout

The loading spout or chute at the end of the conveyor is often adjustable in height and angle. This allows for precise control over the discharge point within the ship's hold, ensuring even loading and maximizing cargo capacity.

-

Dust Suppression System

Mobile ship loading systems are often equipped with dust suppression systems to minimize airborne dust emissions during loading. These systems may include water sprays, misting systems, or other technologies.

-

Operator Control Cabin

An operator cabin is typically mounted on the mobile ship loading system, providing operators with a centralized control point to monitor and control the loading process. The cabin may include advanced control systems for precise adjustments.

-

Power Source Optional

Mobile ship loading systems can be powered by electricity, diesel engines, or a combination of both, depending on the specific requirements and available infrastructure at the port or terminal.

Applications

Mobile Ship Loading Conveyor Systems are versatile and can be used to load a wide range of ships like Barge, Coaster, Handysize, Handymax, Panamax, Capesize, etc. You can use it to load bulk materials listed below.

| Coal | Aggregate & Sand | Grains (Corns, Beans, Wheat, etc) |

| Bauxite | Iron ore | Sugar |

| Wood-chips & Sawdust | Pet Coke | Cement Clinker |

| Fertilizer | Sulphur | Copper Ore |

| Ore Concentrate | Salt | Other Bulk Materials |

Contact Us for Quotes and Prices!

Just let we know what you want, and we will get in touch with you as soon as possible!

English

English